|

KC-888泡沫稳定剂

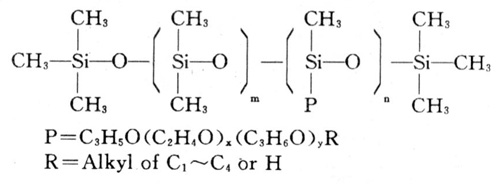

一、结构式

二、性能

KC-888匀泡剂是一种聚硅氧烷一聚醚共聚物表面活性剂,为硅碳键耐水解型泡沫稳定剂。主要应用于生产硬质聚氨酯泡沫塑料,是一种优良的新型产品。

KC-888匀泡剂是科学院与我厂科技人员经过反复研制成功的。得到有关专家及权威人士一致好评,国内外用户单位反映良好,它的综合性能已达到了B8404等国外同类先进产品的水平,1991年4月已通过江苏省省级鉴定,由于它的结构设计合理,该品具有下述突出特点:

1.KC-888在异氰酸醋、聚醚多元醇(如聚醚635、835、1050、4110、403等)及氟碳发泡剂、胺和有机锡催化剂,阻燃剂的体系中有良好的可溶性和稳定性。长期贮存不会浑浊,不会分离,与水共存至少半年性能不变,配制的组合聚醚贮存至少六个月以上发泡性能不变。

2.KC-888具有优异的表面活性和乳化能力,在组合聚醚中(100份)加入KC-888 1.5份,其结果可使塑料泡孔结构细小均匀,高度闭孔,增加泡沫塑料的隔热性能和机械强度、测试对比数据如下:

|

匀泡剂牌号 |

用量 |

F11最大保留量(50℃度 100份聚醚) |

模拟重力场

贮存一年

F11析出情况 |

泡孔情况 |

|

KC-888 |

1.5份 |

31.5份 |

不析出 |

细小均匀密度分布均匀 |

|

德国高斯密特公司 B8404 |

1.5份 |

32份 |

不析出 |

细小均匀密度分布均匀 |

|

美国联碳公司L5420,L580 |

1.5份 |

31份 |

不析出 |

细小均匀密度分布均匀 |

|

国产其它牌号匀泡剂 |

2份-2.5份 |

23-25份 |

均析出 |

泡孔略粗不均匀 |

I.Formula:

| Performance:

KC-888 is a surfactant of polysiloxane-polyether copolymer,and at the same time a silicon-carbide-bond antihydrolytic foam stabilizer. It is a good-quality and new-type product used for manufacturing rigid polyurethane cellula plastic.

KC-888 has been developed by technicians of a Academy of Sciences and our factory. It is highly appraised by relevant experts ,authoritive persons and our clients both at home and abroad. Its overall properties are equal to those of B8404 and of other advanced foreign equivalents. In April of 1991,this product obtained the quality appraisal approval from a provincial authoritive department of Jiangsu Province. It has unique propertiesas follow:

1. It has good solubility and stability in the series of isocyanate,polyether polyol (such as Polyether 635,835,1050,4110 and 403) ,fluorocarbon bubbling agent.amine,organo-tin catalyst and fire retardant. It can not become turbid nor decomposed during long-time storage. It still maintains its performance when it coexists with water for half a year. The conjugate polyether per a certain formula remains good in making foam in spite of half-a-year storage.

2. It has excellent surfaee-aetiveness and emulsification. 100 portions of conjugate polyether with 1.5 portions of KC-888 added in it can make fine.uniform and highly-closed foam and increase the heat-insulation and mechanical strength of cellula plastic.

Tested Constrast Data Are As Follow:

|

Brand No. |

Dose |

Reserved F11 Max. ( 100 portions

of polyether, 50℃) |

Separation of F11 after 1 year of storage in simulated gravity field |

State of foam |

|

KC-888 |

1.5 |

31.5 |

No |

Fine uniform foam and evenly distributed density |

|

B8404 made in Germany |

1.5 |

32 |

No |

″ |

|

L5420.L580 made in USA |

1.5 |

31 |

No |

″ |

|

Other domestic products |

2-7 |

23-25 |

No |

Coarse and uneven |

3、KC-888匀泡剂,可使物料具有良好的流动性,和均匀的密度分布,使模塑制品成型良好,可节约原料、降低成本。测定对比数据见下表:

|

匀泡剂牌号 |

流动性指数Cm/g |

|

KC-888 |

O.47-0.49 |

|

B8404 |

0.48 |

|

L5420,L580 |

0.48 |

|

国产匀泡剂 |

0.36 |

4.KC-888可显著减小甚至消除塑料制品的“剪切线”现象,有利提高电冰箱、冰柜的保温效果,并增强泡沫体与冰箱外壳的粘结强度。用KC-888配制的冰箱料,其剪切线现象明显优于英国ICI的冰箱组合料,(减少剪切线现象是冰箱料的重要要求)。

5.特别适合于低氟聚醚多元醇的工艺发泡配方,有效降低 F11用量50%以上(在半水发泡中,闭孔率达94%以上)。

由于KC-888匀泡剂具有上述优点,它特别适合于组合聚醚的生产.适合于制造冰箱、冰柜隔热材料、夹心板材、保温管材、喷涂施工等。

三、产品质量指标

|

外 观 |

透明粘性液体 |

|

粘度(25℃)MPa·S |

600±120 |

|

浊点(4%水溶液) |

64±5 |

|

相对密度d20°20℃ |

1.07±0.02 |

|

凝固点(℃)≤ |

-12℃±3 |

|

折光率(N2020) |

1.445±0.005 |

|

贮存稳定性 |

12个月 |

|

酸值(MgKOH/g)≤ |

0.25 |

四、贮存与使用注意事项:

1.本品无毒无腐蚀性。

2.密闭贮放在干燥处,保存期12个月以上。

3.低温时本品若发生浑浊,并不影响使用。加热至30℃左右即恢复透明。

4.本品为水溶性物,若泼洒可用水擦洗。

3. KC-888 can make materials(to be foam) fluid well,distribute foam evenly and turn p]astic products into good shape. It can save raw materials and reduce production cost.Tested Contrast Data Are As Follow:

|

Brand No. |

Fluidity index Cm/g |

|

KC-888 |

O.47-0.49 |

|

B8404 |

0.48 |

|

L5420,L580 |

0.48 |

|

Other domestic products |

0.36 |

4. KC-888 can obviously reduce or even eliminate" shear line" phenomenon, so as to increase heat-insulation of frigers and ice cupboards and at the same time increase bond strength between cellula plastic and outer covering of frigers. Cellula plastic with KC-888 in it has less "shear line"phenomenon than that of ICI refrigers made in Britain (It is important for cellula plastic in frigers to have as little "shear line" aspossible ).

5. It is especially fit for the formula for the bubbling process of low-fluoric polyether polyol. It can reduce the dose of F11, by more than 50%(when bubbles in half water state, aperture-closure ratio is over 94%.

Because of the above advantages ,it is especially fit for the production of conjugate polyether.which can be used in the production of heat-insulated materials for frigers and ice cupboards, sandwich boards, beat-insulated pipes and etc.

Ⅲ. Specifications:

|

Appearance |

Transparent viscous liquid

|

|

Viscosity(25℃)MPa·S |

600±120 |

|

Turbidity (4% water solution ) |

64±5 |

|

Relative density d20°20℃ |

1.07±0.02 |

|

Solidity(℃)≤ |

-12℃±3 |

|

Diopter(N2020) |

1.445±0.005 |

|

Storage life |

12 months |

|

Acidity(MgKOH/g)≤ |

0.25 |

IV. Points for Attention to Storage &Application:

1. This product is unpoisonous and uncorrosive.

2. It must be sealed and stored in a dry place for no more than 12 months.

3. It does not matter if the product becomes turbid at low temperature. It will become transparent again if heated to

30℃.

4. It is soluble in water and so it can be washed away by water.

|